NASA-Developed Printable Metal Can Withstand the Heat

NASA has developed a revolutionary printable metal known as GRX-810, which can endure scorching heat of up to 2,000°F for a year with extreme stress. Created at Cleveland’s Glenn Research Center, the heat-resistant alloy is designed to be fabricated by 3D printing for making rocket engine and jet turbine components that are stronger and lighter. While other cost-effective alloys are prone to failure, GRX-810 creates new avenues for space exploration and aviation by reducing the cost and difficulty of producing high-performance components.

The Heat Challenge in Aerospace

Rocket and jet engines run in harsh environments, where temperatures reach 1,900°F to 2,400°F, stressing metals to their limit. Common alloys break down under these conditions or are too expensive to use in 3D printing, restricting designs and increasing costs. Engineers relied on fancy cooling systems or high-end metals to maintain parts, slowing technology development in spacecraft and airplanes. Acquiring a cheap high-temperature alloy for 3D printing metal was a significant challenge to improving aerospace technology.

Designing GRX-810

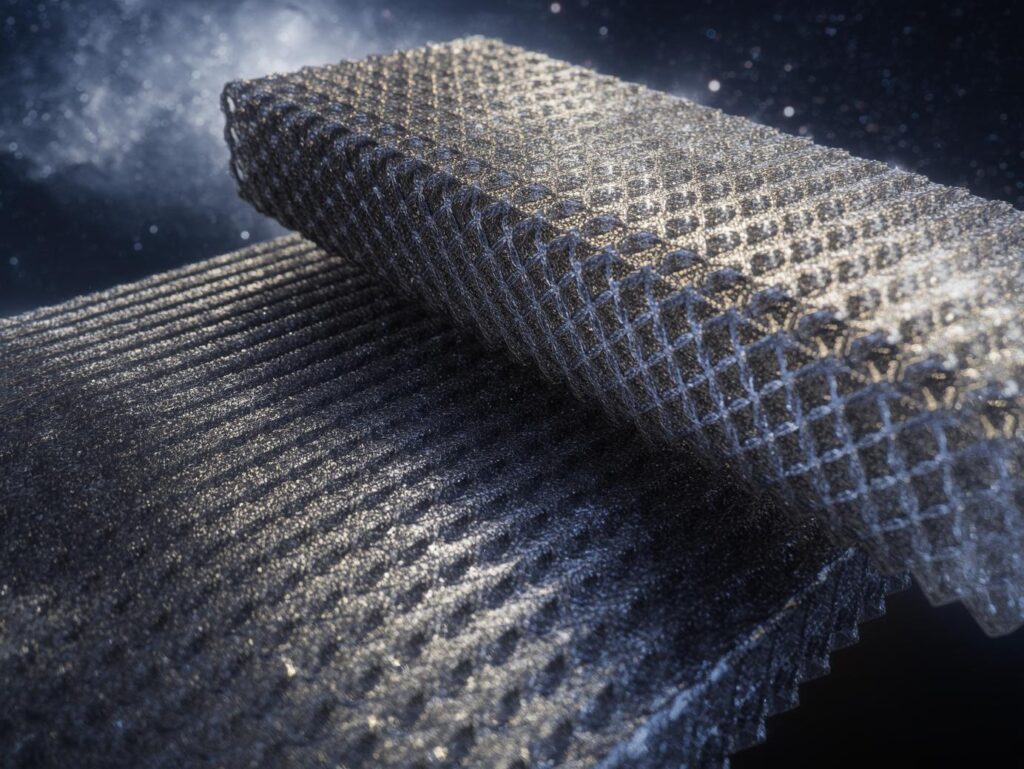

NASA’s team started with a mix of nickel, cobalt, and chromium for toughness. To make it more heat-resistant, they coated minute metal powder particles with ceramic oxides, forming an oxide dispersion strengthened alloy. The process pins defects down, stopping deformation when hot and stressed. They tested 30 different variations using computer modeling in weeks, optimizing the formula effectively. An approach known as resonant acoustic mixing made for uniform coating, making the powder suitable for 3D printed engine parts.

Protective-clad engineers work on telescopic mirrors in a high-tech lab. space printable metal

Why GRX-810 Stands Out

GRX-810 is superior in terms of long-term durability, surviving 1,000 times longer than conventional printable alloys under harsh conditions of extreme heat. It performs well in mid-temperature range (1,900°F to 2,400°F) ideal for rocket engine components such as nozzles and combustors. Its 3D printability enables intricate designs like lightweight lattice-like structures or embedded cooling passages, cutting weight while dissipating heat. NASA’s hot-fire engine testing supports GRX-810 operates with consistency in actual applications.

Changing the Game for Aerospace Uses

This space metal alloy will revolutionize rocket engines for NASA’s Artemis missions and other Mars travels, where heat resistance enables reusable components. In air travel, GRX-810 can be used to upgrade jet turbines so they can operate hotter for increased fuel efficiency and reduced emissions. It is also ideal for hypersonic vehicles traveling at speeds above Mach 5, where intense heat is a recurring issue. Outside of space, this printable metal may upgrade power plant turbines or industrial tools that see high heat.

Partnerships and Commercial Application

Erie, Colorado-based Elementum 3D produces GRX-810 under a license from NASA, making batches ranging from a small quantity to more than a ton. Their research partnership with NASA Glenn Research streamlines production for wider applications. Pioneers are already testing it in turbines and rocket nozzles, confirming its durability. This collaboration illustrates how NASA innovations transition from the laboratory to the industry, bringing 3D-printed engine parts closer.

Effects Beyond Aerospace

GRX-810 reduces the price of high-heat components, relaxing supply chain dependency on scarce metals. In defense, it toughens missiles and ICBMs through durability under harsh conditions. For energy applications, it enhances turbine performance, enabling cleaner power generation. By making affordable, intricate designs possible, this heat-resistant metal propels sustainability and performance in industries, aligning with the world’s objectives for greener technology.

What’s Next for GRX-810

NASA is upscaling testing, employing directed energy deposition to print larger rocket engine components. Scientists are hoping to modify GRX-810 for even more extreme temperatures or reduced weights. Collaborations with firms such as Elementum 3D will widen its uses, from aerospace to production. With the expansion of 3D printing, this aerospace metal alloy may change the way we construct for extreme environments.

In the end of the day, GRX-810 is not another new metal—it’s a game-changer. Engineers have long fought to reconcile strength, cost, and heat resistance in rocket and jet engines for decades. Now, with this printable alloy, they finally have a material that will withstand the heat without breaking the bank.

What’s even more thrilling is the versatility of 3D printing. Rather than adhering to previous designs, engineers can test lighter weights, integral cooling systems, and more intelligent components—all while knowing the material will support extreme stress. That translates to quicker innovation and more dependable machines.

This isn’t simply a matter of rockets going further or jets running better—it’s about opening doors. From powering cleaner energy on the ground to enabling space travel to become more accessible, GRX-810 can transform industries. And since it’s built for long-term use, it makes technology more sustainable as well.

Why This Breakthrough Matters

With space travel and aviation demanding more efficiency, high-temperature alloys such as GRX-810 are essential. They enable rockets to be reusable and jets to be more fuel-efficient, reducing emissions in a world warming up. NASA’s research at NASA Glenn Research drives not just exploration but also innovation on our planet. By solving heat-related issues, GRX-810 opens the door for speedier, cheaper, and cleaner innovation in technology.